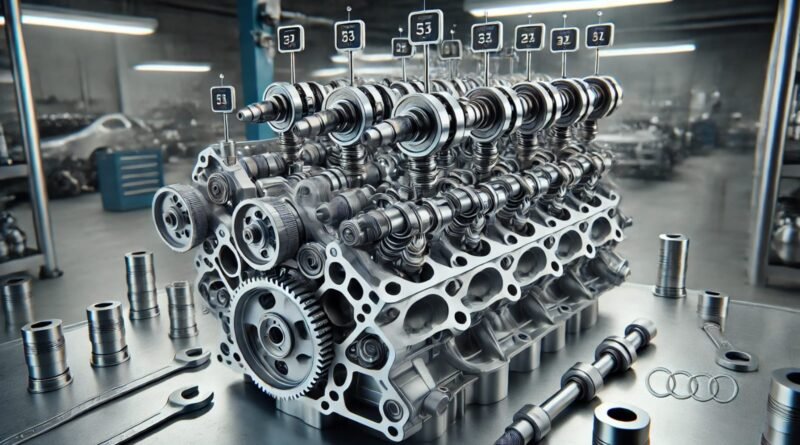

audi 5 cylinder 10v turbo valve shims

The Audi 5 cylinder 10V turbo valve shims play a pivotal role in tuning and maintaining the performance of one of Audi’s most iconic engines. Known for its distinct growl and incredible durability, the 10-valve inline-5 turbocharged engine has won the hearts of enthusiasts worldwide. But as with any high-performance machine, precise tuning is crucial—and that’s where valve shims come in. These small, often overlooked components can drastically affect the efficiency, power output, and longevity of your engine.

What Are Valve Shims and Why Do They Matter?

Valve shims are thin, precision-machined discs placed between the camshaft and the valve lifters or buckets. Their primary role is to control valve clearance—also known as valve lash. In engines like the Audi 5 cylinder 10V turbo, proper valve clearance ensures that the valves open and close at exactly the right time and with the correct lift. Too much clearance results in noisy operation and decreased performance, while too little can lead to valves not fully closing, risking burnt valves and loss of compression.

Understanding the Audi 5 Cylinder 10V Turbo Engine

First introduced in the early 1980s, the Audi 5 cylinder 10V turbo engine gained fame in models like the Audi Quattro and the 200 Turbo. Its unique 5-cylinder layout combines the smoothness of a six-cylinder with the compact size of a four, making it a favorite for both rallying and street performance. The “10V” denotes five cylinders with two valves per cylinder—one intake and one exhaust. When paired with a turbocharger, this configuration delivers robust torque, excellent throttle response, and unmistakable sound.

How Valve Shims Work in the 5 Cylinder Turbo Setup

In the Audi 10V turbo engine, the camshaft pushes directly on a shimmed bucket over the valve stem. This mechanical setup requires precise shim thickness to maintain correct valve lash. Since these engines are solid lifter designs, they don’t self-adjust like hydraulic lifters. That means regular inspection and adjustment are essential, particularly in modified or high-mileage engines.

Role of Valve Clearance in Engine Performance

Valve clearance determines the timing and duration of valve opening. In turbocharged engines like the 5-cylinder 10V, maintaining optimal valve lash is critical for combustion efficiency, turbo spool, and power delivery. Correct clearance allows the valves to seal properly, maximizing compression and ensuring all the combustion energy is transferred into usable force. Neglecting shim adjustment leads to rough idling, reduced boost efficiency, and possible valve damage.

Symptoms of Incorrect Valve Clearance

Signs of improper valve clearance include ticking or tapping noises at idle, hesitation under throttle, rough starts, and reduced fuel economy. In more severe cases, you might experience misfires, excessive exhaust emissions, or even engine overheating. Over time, continued operation with incorrect lash can cause wear to the cam lobes or valve stems, requiring expensive repairs.

How to Check Valve Clearance on a 10V Turbo

Checking valve clearance starts with a cold engine, ideally left overnight. The valve cover must be removed to access the cam and buckets. Using feeler gauges, each valve is measured when the cam lobe is pointed away from the bucket. If the measured gap is outside the manufacturer’s specs (typically 0.20–0.35 mm), the shim must be replaced with one of a different thickness.

Tools Required for Shim Adjustment

To do the job right, you’ll need a few specialized tools. These include a metric feeler gauge set, a micrometer or digital caliper for measuring shims, and a valve shim removal tool (especially helpful for in-situ adjustments). A service manual for your specific Audi model will also come in handy for torque specs and clearance values.

Choosing the Right Valve Shim Size

Selecting the correct shim thickness involves a bit of math. You’ll subtract the current clearance from the desired clearance and adjust the shim size accordingly. Shims are available in increments of 0.05 mm, allowing for fine-tuning. It’s crucial to record measurements and double-check math before reassembly to prevent damaging the valvetrain.

OEM vs Aftermarket Valve Shims for Audi Engines

OEM shims from Audi or VW are made to precise tolerances and use high-grade materials. However, they can be expensive and harder to find. Aftermarket options offer affordability and availability but can vary in quality. Always verify dimensions and material hardness when choosing non-OEM parts to avoid premature wear or failure.

Installation Process for Valve Shims in a 10V Engine

Once the correct shim size is determined, remove the camshaft or use a special tool to depress the bucket and extract the shim. Insert the new shim, reassemble the camshaft, and re-check the clearance. This process is repeated for each valve out of spec. Once done, the valve cover is reinstalled, and the engine is started to verify proper operation.

Maintenance Tips to Keep Shims in Optimal Condition

Regular oil changes and proper valve adjustments every 40,000 to 60,000 miles help prolong shim life. Avoid engine over-revving and ensure proper cam lubrication. Keeping detailed service records helps track when shim inspections are due and what sizes were used previously.

Impact of Valve Shims on Turbo Performance

Valve shims influence how well the engine breathes. In a turbocharged system, proper valve operation ensures maximum exhaust gas flow to the turbo, which affects how quickly it spools and how much boost pressure it can build. Tuners often tweak valve lash slightly to optimize for specific boost levels or RPM ranges, extracting every ounce of performance.

Common Mistakes During Valve Adjustment

One of the most common errors is not resetting the clearance after installing new shims, leading to improper measurements. Others include mixing up shims, using worn feeler gauges, or failing to torque the camshaft correctly. These mistakes can compromise engine reliability and performance.

Upgrading Valve Train Components Alongside Shims

When modifying a 10V turbo for higher horsepower, upgrading the valve springs, retainers, and camshaft can improve valvetrain durability. Stronger springs help prevent valve float at high RPMs, while performance cams can change the timing profile for more aggressive tuning. Shims must then be recalibrated to match the new setup.

Cost Breakdown: Parts and Labor

Expect to pay between $100 and $200 for a full shim kit. Labor costs can range from $300 to $700 depending on whether the camshaft must be removed. Doing it yourself reduces cost significantly but requires mechanical skill and patience.

Where to Source High-Quality Shims for Audi 5-Cylinders

Quality valve shims for Audi 10V engines can be sourced from companies like Supertech, Ferrea, and OEM Volkswagen/Audi suppliers. Online forums and specialty shops like 034Motorsport and ECS Tuning also carry reliable parts and tools for shim replacement.

Frequently Asked Questions

What is the valve clearance specification for Audi 10V turbo engines?

Typically, intake valves are set around 0.20 mm and exhaust valves around 0.35 mm, but always refer to the factory service manual for your exact engine variant.

How often should I check valve shims on a 10V engine?

Every 40,000 to 60,000 miles is a safe interval for inspection, or sooner if you notice performance issues or valve noise.

Can incorrect valve shims cause turbo lag?

Yes, poor valve operation can affect exhaust gas flow, reducing turbo response and overall boost efficiency.

Is it okay to reuse old valve shims?

If they’re not worn or damaged and still within tolerance, they can be reused. Always inspect for pitting or warping.

Are valve shims the same for all Audi 5-cylinder engines?

No, shim sizes and designs vary by engine model. Always use parts specified for the 10V turbo configuration.